Versatile printed solutions for a safe and

high-performance battery system

What is VERSAPRINT?

Versaprint is a 3-year Horizon project that brings innovation to batteries in the transport sector, improving their safety, manufacturability, sustainability, performance, and lifetime. Its main goal is to boost the circular economy and the cost-effectiveness of the battery value chain.

By 2D/3D printing on the cell or module components, VERSAPRINT offers technical solutions (Building Blocks – BBs) that contribute to tackling safety issues, enhancing performance, and decreasing cost and environmental impact. These versatile solutions are adaptable to different types of cell formats (prismatic or pouch) and will not be chemistry-dependant.

Watch our project video now!

Specific objectives of the project

Implementation

At cell unit level

At module level

Automotive

Demonstration of the benefits of VERSAPRINT technologies for the automotive sector

Aeronautics

Demonstration of the benefits of VERSAPRINT technologies for the aeronautics sector

Waterbone and others

Virtual demonstration of the VERSAPRINT advancements for waterborne sector and replicability for other mobile and stationary applications

Transversal approach

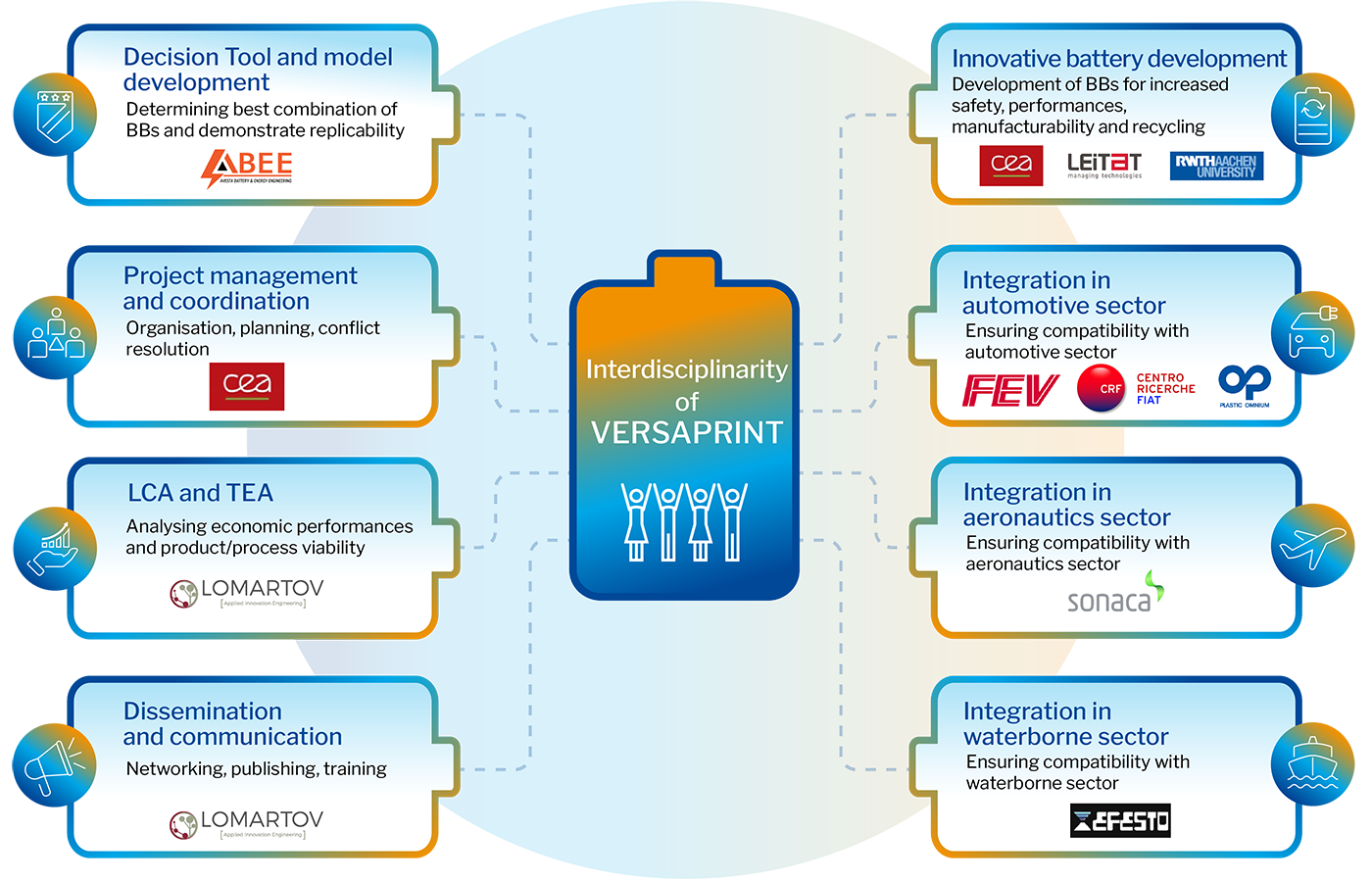

VERSAPRINT acts as close as possible from the heart of the battery system, tackling performance improvement at the most appropriate level and optimising the system as a multi-physical equation to be solved with a multi-criteria and interdisciplinary methodology.